$ 717.14 Original price was: $ 717.14.$ 615.48Current price is: $ 615.48.

Shop Mitutoyo 345-251-30 Digital Inside Micrometer, Caliper Type. Ensure precise bore and groove measurements with high accuracy and easy digital readout.

The Mitutoyo 345-251-30 Digital Inside Micrometer (Caliper Type) is engineered for highly precise internal diameter and groove measurements. With its advanced digital display, it allows users to read measurements quickly and clearly, reducing human error. Built with Mitutoyo’s renowned accuracy, it is designed for professionals who require reliability and efficiency in machining, quality control, and inspection processes. Its robust construction ensures long service life, even in demanding industrial environments.

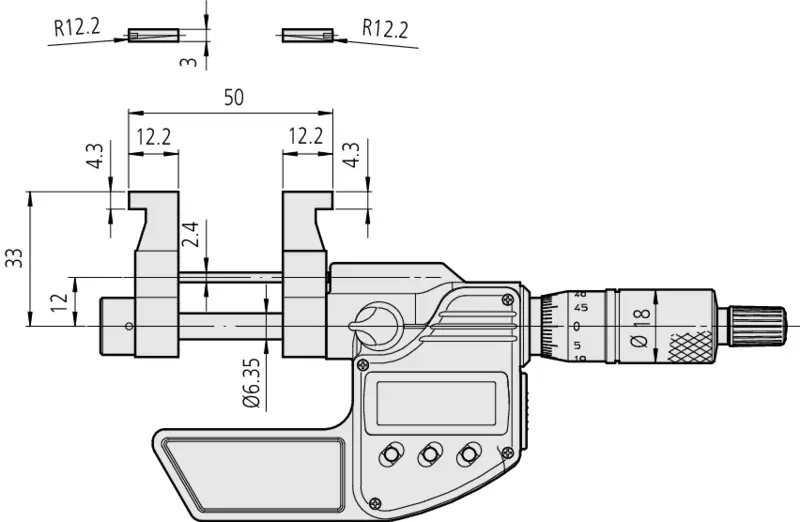

The Mitutoyo 345-251-30 offers a measuring range of 5–30 mm with a resolution of 0.001 mm and an accuracy of ±3 µm, making it suitable for high-precision bore and groove measurements. Featuring an ergonomic caliper-type design, the instrument ensures ease of handling while maintaining stable performance. The digital LCD readout provides clear, immediate readings. It supports Origin Set and Data Hold functions for streamlined workflow, and the battery-powered operation enhances mobility in workshop and inspection settings.

Choosing the Mitutoyo 345-251-30 means investing in uncompromising precision for internal measurements. Unlike conventional micrometers, this digital caliper-type design combines accuracy with ease of use, minimizing operator fatigue. Its compact size allows measurements in confined spaces, while the robust construction ensures durability under continuous use. This tool is a perfect balance of Mitutoyo innovation, reliability, and convenience—making it an ideal choice for quality-driven professionals.

Measuring internal diameters and grooves with traditional tools can be challenging, error-prone, and time-consuming. The Mitutoyo 345-251-30 solves this by delivering digital precision with instant readability, reducing operator interpretation errors. It provides reliable results even in high-volume inspection environments where accuracy and efficiency are critical. By simplifying complex bore measurements, it ensures consistent product quality, enhances productivity, and reduces costly rework in machining and manufacturing operations.

During machining, operators quickly validate internal diameters and groove widths before the part leaves the fixture. The digital readout eliminates guesswork, while a compact, caliper‑type body reaches tight bores without disassembly. Consistent technique supports repeatable results across shifts, enabling immediate tool offsets and reducing scrap. Data capture streamlines SPC, so trends are spotted early and corrective actions happen before defects multiply.

Quality teams use the instrument to verify IDs, counterbores, and snap‑ring grooves on received parts. Fast, repeatable readings allow 100% checks on critical dimensions or efficient sampling on large lots. Clear digital values minimize interpretation errors in mixed‑skill teams. Results can be logged for traceability, strengthening supplier scorecards, resolving disputes with evidence, and ensuring only conforming components move to production or assembly.

Before pressing bearings, bushings, or seals, technicians verify seating bores to prevent costly rework and premature failures. The tool’s slim measuring contacts reach features that standard calipers struggle to access, producing confident pass/fail decisions in seconds. Simple operation suits fast‑paced stations, while consistent readings reduce variability between operators. By catching undersize/oversize conditions early, the line maintains throughput without sacrificing dimensional integrity.

Service engineers measure internal wear on cylinders, housings, and sleeves without complex teardown. Repeatable digital measurements let teams trend diameter growth over time, correlate with vibration or leakage data, and plan maintenance windows instead of reacting to breakdowns. The portable, durable instrument performs reliably on the shop floor, supporting root‑cause analysis and helping prioritize component replacement to extend equipment life and control total maintenance cost.

| Feature | Details | Benefit |

|---|---|---|

| Model | Mitutoyo 345-251-30 (Digital Inside Micrometer, Caliper Type) | Ensures precise and reliable bore and groove measurements |

| Measuring Range | 5 – 30 mm | Covers small to medium bores for versatile use |

| Resolution | 0.001 mm | Enables highly accurate dimensional readings |

| Accuracy | ±3 µm | Guarantees confidence in precision-critical applications |

| Design | Caliper-type with interchangeable measuring contacts | Provides flexibility to measure different internal geometries |

| Display | Large digital LCD readout | Clear, quick, and error-free reading |

| Functions | Origin Set, Zero/ABS, Data Hold | Enhances workflow efficiency and consistency |

| Power Supply | SR44 (or equivalent) battery | Long-lasting, portable use without dependency on external power |

| Material & Build | Hardened stainless steel body with precision ground jaws | High durability and stability under industrial use |

| Repeatability | 0.002 mm | Supports consistent results across repeated measurements |

| Ergonomics | Lightweight, balanced structure | Reduces operator fatigue during prolonged inspections |

| Data Output | SPC-compatible (optional cable connection) | Allows measurement data logging for quality control |

| Operating Environment | Workshop-ready, temperature stable | Reliable use in inspection rooms and production floors |

| Use Cases | Bore, counterbore, snap-ring groove, and seat measurement | Widely applicable in machining, assembly, and quality assurance |

|

Digital Inside Microm. Caliper Type |

| 5-30mm | |

| Mitutoyo Part Number: 345-250-30 | |

| More Info | |

|

Digital Inside Microm. Caliper Type |

| 25-50mm | |

| Mitutoyo Part Number: 345-251-30 | |

| More Info | |

|

Digital Inside Microm. Caliper Type |

| Inch/Metric, 0,2-1,2″ | |

| Mitutoyo Part Number: 345-350-30 | |

| For more : Contact us | |

|

Digital Inside Microm. Caliper Type |

| Inch/Metric, 1-2″ | |

| Mitutoyo Part Number: 345-351-30 | |

| For more : Contact us |

Optional accessories:

|

Digimatic Cable with Data Button IP Type |

| 1m, Micrometer Type | |

| Mitutoyo Part Number: 05CZA662 | |

| For more : Contact us | |

|

Digimatic Cable with Data Button IP Type |

| 2m, Micrometer Type | |

| Mitutoyo Part Number: 05CZA663 | |

| For more : Contact us | |

|

USB Input Tool Direct (Digimatic to USB) |

| 2m Cable, Digimatic/Digimatic 2, Flat Straight Type | |

| Mitutoyo Part Number: 06AFM380F | |

| For more : Contact us | |

|

U-WAVE fit, Buzzer Type |

| Wireless Transmitter for Micrometer/Indicator | |

| Mitutoyo Part Number: 264-623 | |

| For more : Contact us | |

|

U-WAVE fit, IP67 Type |

| Wireless Transmitter for Micrometer/Indicator | |

| Mitutoyo Part Number: 264-622 | |

| For more : Contact us | |

|

U-WAVE fit Bluetooth, Buzzer Type |

| Wireless Transmitter for Micrometer/Indicator | |

| Mitutoyo Part Number: 264-627 | |

| For more : Contact us | |

|

U-WAVE fit Bluetooth, IP67 Type |

| Wireless Transmitter for Micrometer/Indicator | |

| Mitutoyo Part Number: 264-626 | |

| For more : Contact us | |

|

Connection Unit for IP Caliper, Micrometer |

| with Data Button for U-WAVE fit, U-WAVE fit Bluetooth | |

| Mitutoyo Part Number: 02AZF310 | |

| For more : Contact us |

Consumable spares:

|

Battery SR44 1.5V |

| Mitutoyo Part Number: 938882 | |

| For more : Contact us |

For expert guidance before placing your order.

Warranty – 1-year warranty for your peace of mind.

Global Shipping – We ship worldwide with secure packaging and reliable delivery.

Technical Support – Contact us for professional after-sales technical assistance.