PANASONIC | INDUSTRY

DIGITAL MARK SENSOR

LX-100 Series

Unmatched Color Discrimination

Detect any mark with supreme accuracy. The LX-100 Series utilizes a high-precision, 3-LED (R, G, B) system to automatically select the optimal color combination for stable, rapid response sensing.

Advanced Sensing Capabilities

The LX-100 is engineered for performance, combining three core technologies into one compact sensor.

01

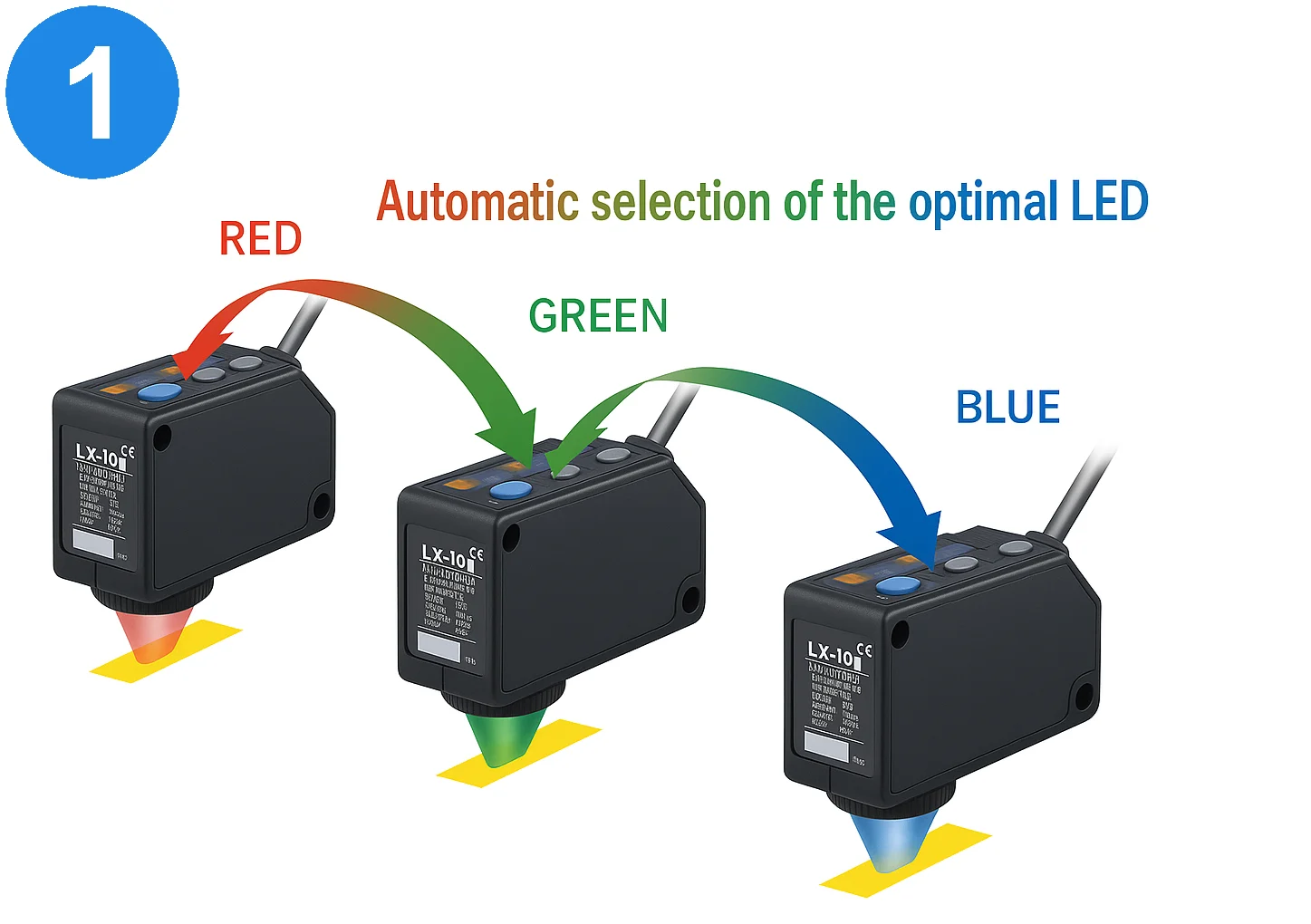

3-LED R•G•B Light Source

Integrates Red, Green, and Blue LEDs to detect any mark color. The automatic optimal LED selection function ensures stable and reliable sensing by choosing the best light for the mark/base contrast.

02

High Precision Coaxial Optics

A unique coaxial reflective optical system with a 12-bit A/D converter enables high-precision sensing and stable detection of even subtle differences in color and patterns.

03

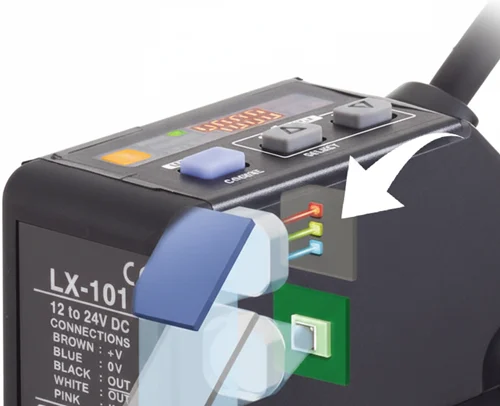

4-Digit Digital Display

Makes setup and verification intuitive and simple. The MODE NAVI operation system with 6 indicators allows for quick configuration of detection modes, timers, and thresholds at a glance.

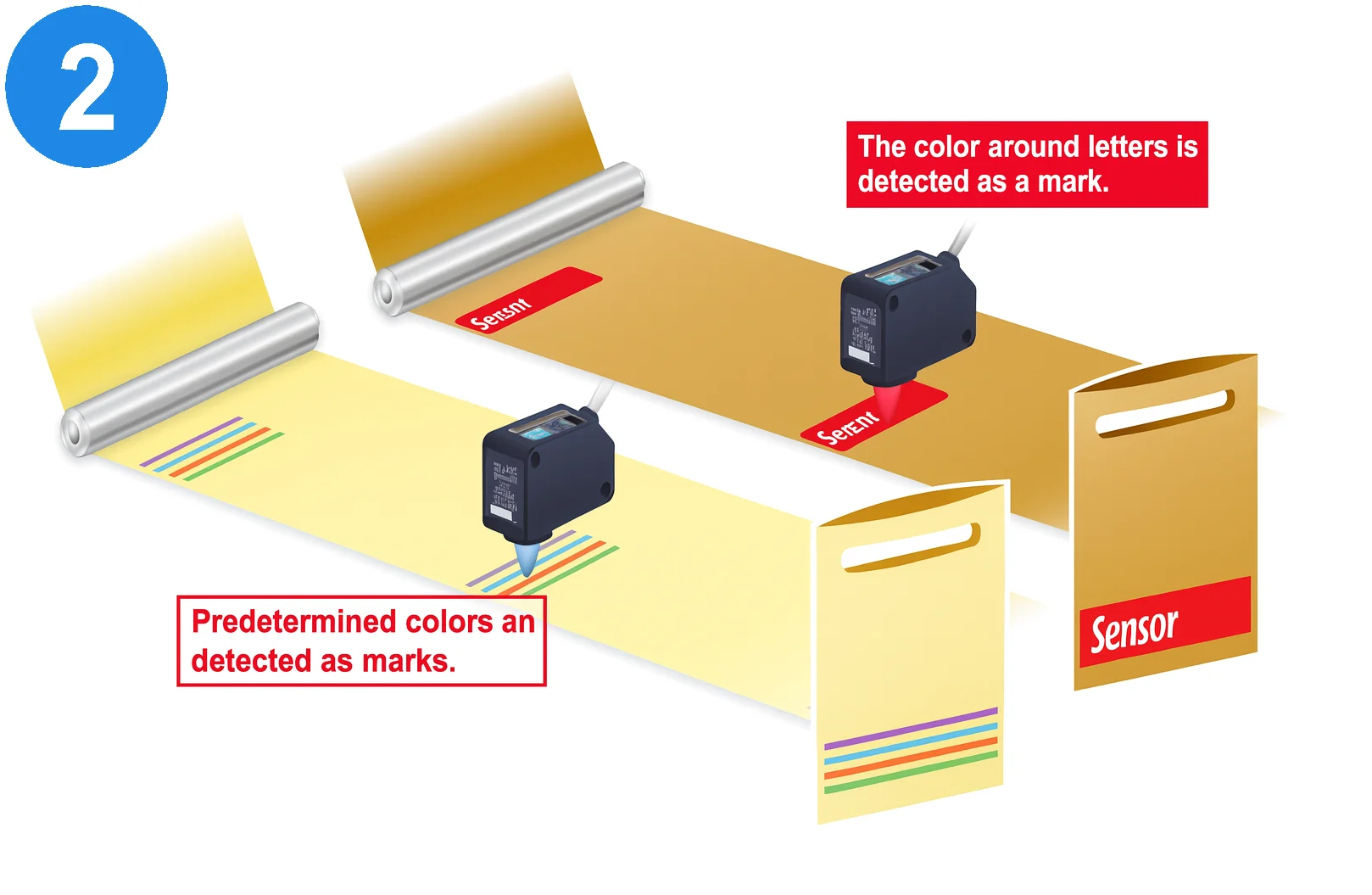

Dual Detection Modes

Flexible for Any Application

Select the perfect mode to match your application’s needs, whether it’s for ultra-quick sensing or high-precision color discrimination.

1. Mark Mode (Ultra High-Speed)

Automatically selects a single color from the 3 R•G•B LEDs for the best contrast, enabling an ultra-quick response time of 45 µs. Perfect for high-speed packaging lines.

2. Color Mode (High Precision)

Utilizes all 3 R•G•B LEDs and analyzes the R•G•B ratio to perform high-precision 1/4,000-resolution judgments. Ideal for discriminating between similar colors and patterns.

Simple Teaching Process

Features a 2-level teaching method. Just align the spot on the mark and press the ON key. It’s that simple. Full auto-teaching and 1-level teaching options are also available.

Timer Setting

Configure On-delay, Off-delay, or One-shot timer operations from 1 ms to 500 ms.

Key Lock Function

Prevent accidental changes by locking the settings. Choose between locking all keys or only the teaching key.

ECO Mode

Reduce power consumption by turning off the digital display during operation. The display reactivates when keys are pressed.

Reset to Factory

Easily revert all settings to their default factory values for a clean setup.

Key Features & Specifications

| Feature | Details | Benefit |

|---|---|---|

| Detection Principle | Coaxial reflective type with RGB LED light source | Ensures stable sensing on reflective or textured surfaces |

| LED Light Source | Red (640 nm), Green (525 nm), Blue (470 nm) | Automatically selects optimal color for the best contrast |

| Spot Size | 1 × 5 mm at 10 mm distance | Enables precise detection of small marks |

| Sensing Range | 10 ± 3 mm | Flexible positioning for diverse applications |

| Response Time | Mark Mode: ≤ 45 µs / Color Mode: ≤ 150 µs | Suitable for ultra‑fast packaging and printing lines |

| Display Type | 4‑digit LED with Mode NAVI indicators | Easy setup, monitoring, and numerical threshold adjustment |

| Output Type | NPN / PNP open‑collector transistor, 2 outputs | Compatible with most PLC systems |

| Supply Voltage | 12–24 V DC ± 10 % | Standard industrial power compatibility |

| Material & Build | PBT enclosure, polycarbonate window, glass lens | Durable and resistant to dust and vibration |

| Protection Rating | IP67 (IEC) | Waterproof and dustproof for harsh environments |

| Ambient Temperature | −10 to +55 °C | Reliable operation in manufacturing environments |

| Ambient Illumination | ≤ 3,000 lx (incandescent) | Reduces interference from ambient light |

| Teaching Methods | 1‑level, 2‑level, full‑auto teaching | Simplifies commissioning and calibration |

| Digital Resolution | 12‑bit A/D converter (1/14,000) | Provides precise RGB ratio detection |

| Indicators | RUN / TEACH / ADJ / COLOR / TIMER / PRO | Quick mode recognition for operators |

| Output Protection | Short‑circuit and reverse polarity protection | Enhances reliability and safety |

| Dimensions | 57 × 24 × 38 mm | Compact form for easy integration |

| Weight | Approx. 120 g (cable type), 95 g (plug‑in type) | Lightweight for easy mounting |

Model Variants

| Model | Output Type | Connector Type | Sensing Range |

| LX‑101 | NPN | Fixed cable | 10 ± 3 mm |

| LX‑101‑P | PNP | Fixed cable | 10 ± 3 mm |

| LX‑101‑Z | NPN | Plug‑in connector | 10 ± 3 mm |

| LX‑101‑P‑Z | PNP | Plug‑in connector | 10 ± 3 mm |

Commercial Information

| Parameter | Value |

| Brand | Panasonic Industry |

| Series | LX‑100 |

| Country of Origin | Japan |

| Weight | 120 g (approx.) |

| Compliance | CE, UKCA, UL Recognition |

| Warranty | 1 Year (standard manufacturer warranty) |

The Applications

1. High-Speed Mark Detection on Flow-Wrap Packaging

In modern food packaging lines, flow-wrap machines run at extreme speeds, requiring sensors that react in microseconds. The LX-100’s ultra-fast 45 µs response and automatic LED colour optimization ensure each printed registration mark is detected precisely, even when film colour or brightness varies between batches. Its small 1 × 5 mm spot size enables pinpoint accuracy on narrow print marks, minimizing waste from cutting errors and keeping packaging aligned with the sealing jaw positions.

2. Detecting Marks on Transparent or Glossy Films

Films with high reflectivity or transparency often cause false triggers with standard photoelectric sensors. The LX-100’s coaxial reflective optical design and anti-glare glass lens effectively suppress surface reflections, maintaining stable detection of subtle contrast differences between printed marks and film backgrounds. This makes it ideal for cosmetic pouches, shrink wraps, and laminated snack packaging where standard diffuse sensors fail to differentiate between reflection and printed ink.

3. Color Verification in Label and Sleeve Application

When applying printed labels or shrink sleeves, ensuring the correct color zone or registration band is essential. The LX-100’s RGB analysis mode evaluates the reflected light ratio across all three LED colors, distinguishing even minor hue differences between reference marks. This prevents incorrect sleeve orientation or mislabeling caused by slight ink variations or print shifts. Its numeric threshold display allows operators to quickly verify the sensor’s color judgment value for precise control during high-volume label application.

4. Precision Registration for Multi-Color Printing and Cutting

In print-and-cut packaging lines, multiple color layers and complex backgrounds make it difficult to identify registration marks. The LX-100 automatically selects the most responsive LED color and utilizes 12-bit A/D signal processing to maintain consistent mark detection even as surface brightness changes. This ensures accurate synchronization between the print and cutter, preventing offset errors and reducing production scrap. Its stable detection performance also supports rapid product changeovers, critical for packaging converters managing short print runs.

Technical Advantages

Automatic LED Optimization: Selects the best LED color for maximum contrast.

High Precision RGB Discrimination: Differentiates even subtle color differences.

Digital D‑Code Readout: Enables quick setup verification and remote support.

Compact & Lightweight Design: Fits in tight machine spaces with minimal wiring.

Multiple Teaching Modes: Enables easy setup for different packaging materials.

ECO Display Function: Reduces power consumption and enhances display clarity.

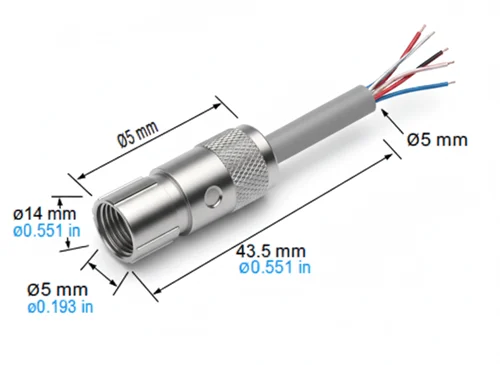

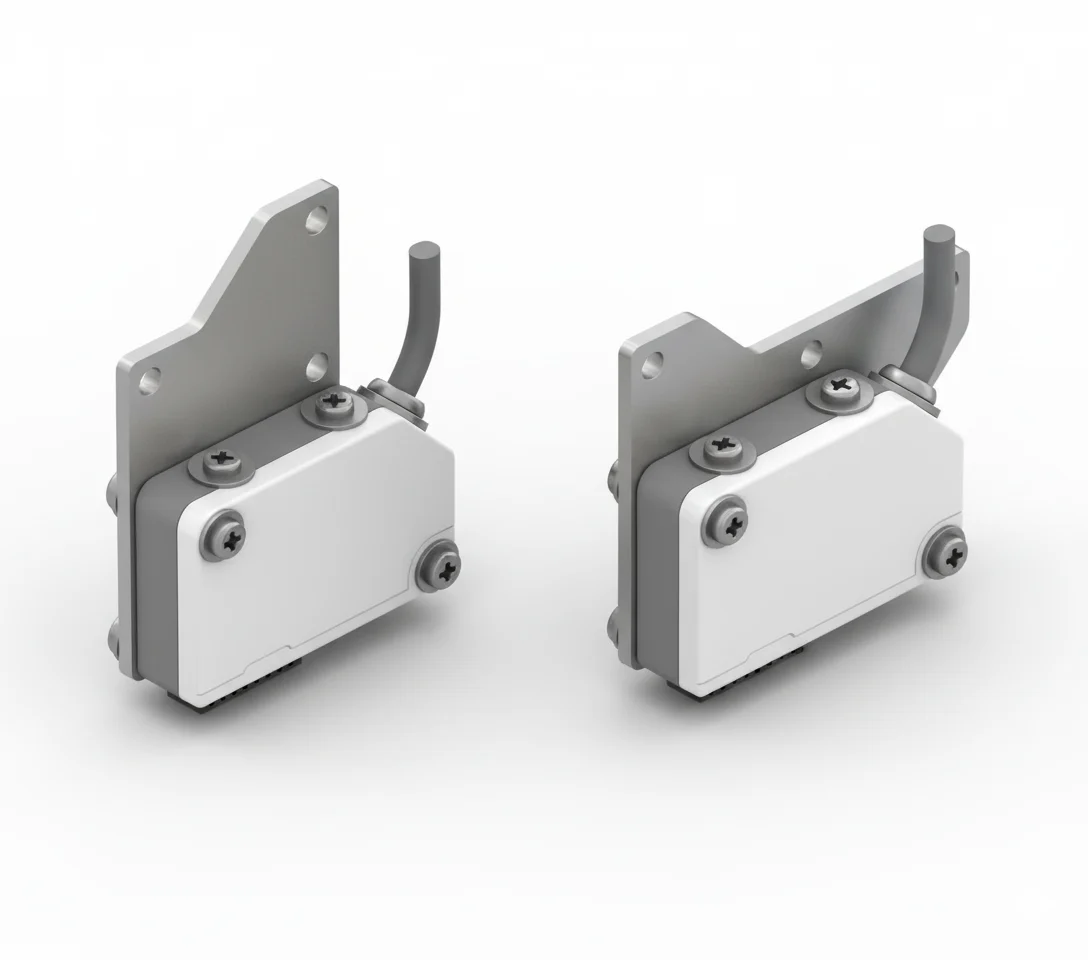

Accessories

| Type | Model No. | Description |

| Mounting Bracket | MS‑LX‑1 / MS‑LX‑2 | Brackets for side or rear mounting |

| Cable (Straight) | CN‑24B‑C2 / CN‑24B‑C5 | 2 m / 5 m straight cable, 4‑core Ø5 mm |

| Cable (Elbow) | CN‑24BL‑C2 / CN‑24BL‑C5 | 2 m / 5 m elbow‑type cable, 4‑core Ø5 mm |

Contact Us

For technical assistance, maintenance service, or to purchase the Panasonic LX-100 digital mark sensor , please reach out to our team.

Our engineers can help you confirm model compatibility, connection layout, and accessory requirements before ordering.

Email: sales@inosaki.com

Product Page: LX-100 Series – Panasonic Thin-type Ionizer